Shale Shock: Hydraulic Fracturing

CONCERNS: WATER, WATER, EVERYWHERE

As always with breakthroughs in technology, there are associated concerns. In the case of shale gas, questions have been raised about the environmental safety of the hydraulic fracturing process and the management of the volumes of water used to fracture shale.

Shale Shock: Hydraulic Fracturing

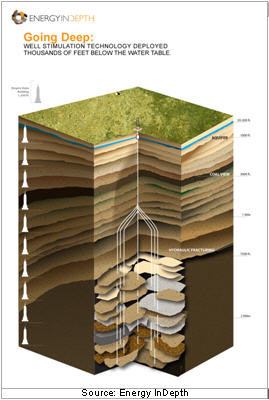

Hydraulic fracturing (fracking) is the method used to make hard shale rock more porous, thus allowing natural gas to flow through the shale to the wellbore. First, producers drill into the earth several thousand feet until they reach the natural gas reservoir.  Next, steel casings are inserted to a depth of 1,000 to 3,000 feet, and the space between the casing and the drilled hole is filled with cement to stabilize the well and prevent any leakage. After the cement has set, this process is repeated, using a series of successively smaller casings until the reservoir is reached, usually a distance of 6,000 to 10,000 feet. There are numerous state and federal regulations that govern the casing and cementing process, for more information please visit Energy InDepth.

Next, steel casings are inserted to a depth of 1,000 to 3,000 feet, and the space between the casing and the drilled hole is filled with cement to stabilize the well and prevent any leakage. After the cement has set, this process is repeated, using a series of successively smaller casings until the reservoir is reached, usually a distance of 6,000 to 10,000 feet. There are numerous state and federal regulations that govern the casing and cementing process, for more information please visit Energy InDepth.

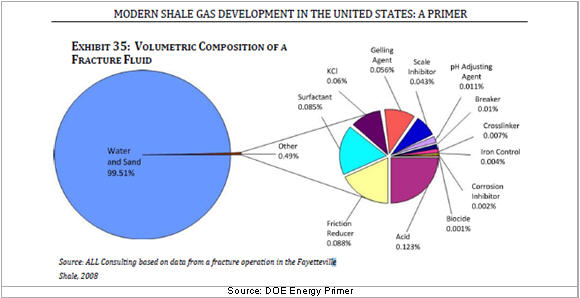

Once the drilling and casing is complete, typically 3 to 5 million gallons of water, mixed with sand and fractional amounts of chemical additives, are pumped into the wellhead at high pressure, creating cracks in the rock beds. Several videos provide a detailed explanation of the fracking process. Please click here for a video courtesy of ExxonMobil. For a more in depth look into fracking, please see this API video.

The hydraulic fracturing mixture is 95 percent water, 4.5 percent sand and 0.5 percent chemical additives formulated to promote gelling and cleaning according to the Ground Water Protection Council and U.S Department of Energy, which can be found here. Fracturing fluid formulas vary slightly among production sites in accordance with the unique requirements of each site’s geology. Many of the additives used in fracturing fluids are ingredients in common household goods, such as candy, soaps, and ice-cream.

The initial fracturing stage may use hydrochloric acid to clean up the wellbore damage done during drilling and cementing. Gelling agents, based on water-soluble polymers such as vegetable- derived guar gum, adjust fracturing fluid viscosity. More information may be found from the CRS report, Unconventional Gas Shales: Development, Technology and Policy Issues.

Concerns have been raised by environmental groups and citizens regarding the chemicals used during the fracking process and claims persist that fracking fluids contaminate local drinking water reservoirs. For this reason, interest groups are actively lobbying for fracturing fluids to be federally regulated under the Safe Drinking Water Act (SDWA), requiring disclosure of fracturing fluid formulas to the public.

State & Federal Oversight

Hydraulic fracturing fluids are exempted from federal SDWA oversight. However there are numerous state regulations that govern their use. Of the 27 states that support 99.9 percent of all natural gas exploration activities nationwide, all 27 have permitting requirements in place that govern the siting, drilling, completion and operation of wells, including hydraulic fracturing.

Shale producers point out that at no point do fracturing fluids come into contact with drinking water reservoirs. In fact, hydraulic fracturing takes place thousands of feet below the water table and thus are isolated from drinking water by thousands of feet and millions of tons of impermeable rock. The gas industry also notes that more than one million wells have been fractured without drinking water contamination. Should a surface spill or incident occur, state regulators have testified that they have sufficient authority to prosecute the offending parties so that incidents do not occur in the future.

Industry contests that the composition of fracturing fluids is proprietary information and that fracturing fluids are physically separated from the water table by cement and steel casings, thousands of feet, and tons of impermeable rock. They say the practice is strictly regulated by the states and it has been reviewed and declared safe by the Environmental Protection Agency as well as other environmental oversight groups.

Industry says shale producers already comply with federal and state disclosure requirements that require regulators, first responders and medical personnel to have access to information concerning the chemical composition of fracturing fluids at all well sites, so that they can appropriately protect and safeguard human health and the environment. New York, Pennsylvania, Wyoming and Texas publicly publish fracturing ingredients online. Colorado is contemplating implementing its own regulations governing the disclosure of fracking fluids. For further information on fracking fluids, please visit FracFocus.

Federal laws provide oversight for the process of drilling, completion and waste water management. Operators comply with a range of federal chemical record keeping and reporting requirements, including the Occupation Safety and Health Administration (OSHA) Hazard Communication Standard. They also must provide local emergency personnel with chemical information.

Producers, regulators, citizens and environmentalists all are in agreement that any irresponsible actors should be prosecuted. Enforcement of the existing state laws not only protects the groundwater, it provides reassurance to the community and shale producers that shale wells are being properly managed and are sustainable. Hydraulic fracturing is vital to shale gas production and regulatory uncertainty regarding the process could prevent the full-scale development of the U.S. shale gas resource base. And without hydraulic fracturing, it is neither economical nor technically feasible to extract natural gas from shale at this time.